Architectural Shapes

The essence of architecture lies far beyond four walls and a roof — it’s about emotions embodied in form, material, color, and the way they come together.

The curved lines of window frames, the moldings and cornices, the basic shapes and other architectural forms, the smoothness and straight edge of a column — these are not just details, but meaning itself, the meaning a building carries within.

Each of these elements gives architecture character, completeness, individuality, and a unique style that can’t be mistaken for anything else. And when such details are crafted from foam, true magic happens. Everything becomes easier — production, transport, installation — and the design itself feels light and liberated, allowing any creative vision to come to life.

Welcome to the new era of architectural foam shapes — where imagination meets innovation, and craftsmanship meets speed. It’s where a designer’s sketch turns into reality not in months, but in days — and where beauty no longer has to weigh a ton. Because architecture isn’t just what you see. It’s what you feel when you see it.

Sculpting Light: The Language of Architectural Forms

Every building has a rhythm, a heartbeat. Architectural shapes and geometric forms are what make that heartbeat visible — they give structure to emotion, proportion to story.

A perfectly balanced trim line draws the eye and settles the mind. A bold column brings quiet authority. Even the simplest foam cornice can change the mood of an entire façade — giving it presence, warmth, and harmony. Ever walked down a street and felt that one building just had… something?

That instant connection isn’t luck — it’s the precision of proportion. It’s form done right. What’s fascinating is how light plays with these shapes. Foam doesn’t just create forms; it sculpts light and shadow, bringing a tactile softness that stone often can’t.

And because foam can be cut and molded with surgical precision, designers are free to experiment — chasing that perfect blend of geometry and grace without worrying about cost or weight.

When shape, texture, and proportion align, architecture becomes poetry written in sunlight.

The Foam Revolution: Lighter, Faster, Smarter

Materials define the pace of progress. Stone defined permanence. Concrete defined strength.

But architectural shapes? They define freedom. It’s not just about reducing cost or time. It’s about unlocking creativity that’s been boxed in for decades by logistics and gravity.

- Ultra-light, ultra-strong. You can lift even a massive decorative element with one hand.

- Design without limits. If you can sketch it, it can be cut — arches, scrolls, intricate logos, sculptural façades.

- Weatherproof and tough. Coated with advanced polymers, foam geometric shapes handle sun, wind, and rain for years without warping.

- Fast turnarounds. Projects that once took weeks can now be delivered in days.

- Smart budgets. Lower production, transport, and installation costs — with the same visual impact as stone.

One of our clients, a mid-sized design-build firm in Texas, once told us, “You saved us four weeks and fifteen grand — and the client thought it was stone.”

That’s the power of a material that looks luxurious but behaves like innovation. And yet, the real magic lies in its adaptability. Whether it’s a high-rise project in Chicago or a resort renovation in Miami, geometric forms itself — literally and figuratively — to your vision. That’s what keeps modern architecture agile and human.

Framing Emotion: The Beauty of Architectural Window Shapes

Windows don’t just let in light — they tell the building’s story. They frame the way the world sees us, and the way we see out. That’s why geometric shapes matter so much. A simple arch or decorative frame can turn a flat wall into a face — expressive, proud, unforgettable.

Rounded frames bring grace and tradition.

Angular or asymmetrical designs scream modern boldness. And foam lets architects move between those worlds effortlessly. Foam window surrounds are also a dream to install. They’re lightweight, cut-to-fit, and adaptable to almost any surface — from stucco to concrete to siding.

“Can we match the existing style of our 1930s building?” Absolutely. That’s the magic of foam — it replicates any era, any aesthetic, down to the last curve.

Take a project in Florida — a boutique hotel renovation. The client wanted classical window crowns but had a tight schedule before tourist season. Using custom geometric shapes, they refaced the entire façade in under two weeks. The result? Instagram-worthy architecture that looked handcrafted in stone — but wasn’t. And beyond aesthetics, these foam frames improve insulation and reduce long-term maintenance. Beauty isn’t just skin-deep — it’s built for endurance.

Beyond Symmetry: Custom Decorative Architectural EIFS Foam Shapes

Every truly great building has one thing in common — it feels personal. That’s the beauty of custom decorative architectural EIFS foam geometric shapes. No two designs need to be the same.

Every truly great building has one thing in common — it feels personal. That’s the beauty of custom decorative architectural EIFS foam geometric shapes. No two designs need to be the same.

Each piece can carry its own personality — bold, minimalist, ornate, or futuristic. Unlike factory-molded materials, foam gives artisans and architects room to dream. And that’s when the magic happens — when a designer’s sketch turns into a three-dimensional sculpture that redefines an entire street view.

Here’s what makes customization more than a buzzword:

Personal storytelling through form. Each line says something — about the brand, the architect, the era.

Functional art. It’s not just about decoration. These elements bring shadow and rhythm into the space, adding depth and character — turning flat walls into vibrant 3D façades that are simply fascinating to look at.

Easy adaptability to any type of project. Foam makes it possible to create richer, more expressive designs — from subtle accents to large, monumental architectural elements.

There’s a corporate headquarters in Arizona that wanted its façade to echo the region’s desert dunes — soft curves, flowing motion. It’s not always possible to achieve everything with traditional materials — especially in today’s world, where speed and quality are equally essential.

Foam, in this sense, is the perfect choice: it makes any design simple and effortless to produce. The building doesn’t just stand still — it seems to come alive and breathe, its appearance becoming vibrant and dynamic.

The final result of our work isn’t just customization as an option — it’s something truly meaningful: the effect of authenticity, uniqueness, liveliness, and originality.

Architectural Foam Shapes: The Advantages of This Choice

In a world full of repetition, custom is the new luxury.

In a world full of repetition, custom is the new luxury.

That’s why working with a partner who creates tailor-made architectural foam shapes makes all the difference. We don’t do “one-size-fits-all.” Every project is personal — from dimensions to color, from surface texture to curvature.

Need a cornice that matches the rhythm of your building’s façade? Done. Want window trims that echo your corporate identity colors? We’ve got you. Require columns that blend contemporary design with classical proportions? Absolutely.

We collaborate with designers and builders to choose the right foam density, the ideal coating, and even the finishing texture — matte, glossy, stone-like, or brushed. Every step is a dialogue.

Unlike mass-produced moldings that demand you to adapt, our foam geometric shapes adapt to you. That’s the beauty of real customization — it fits, it flows, it belongs. Because in architecture, there’s nothing more frustrating than almost right.

We make sure your design is exactly right — every curve, every contour, every nuance.

Shapes That Build Identity

Think of the look of any beautiful, unforgettable city — New York, Miami, Chicago. What makes it stand out and stay in your memory? It’s not just the height of the buildings, but their shapes and the harmony between them.

Why do we love palaces and elegant architecture? Because they have personality — a distinctive character and presence that set them apart from the standard buildings we forget by tomorrow.

That’s exactly what foam geometric shapes do — they subtly yet clearly give each building its own identity, creating the kind of look you want to remember.

Today, you can find them everywhere:

- Luxury resorts that use ornate cornices to evoke heritage and opulence.

- Retail chains that need identical façade accents across dozens of states.

- Historic renovations where lightweight replication saves fragile structures.

- High-end residentials where subtle window trims and crown details add value without excess cost.

Because here’s the truth: when architecture feels personal, people connect with it emotionally. And that connection builds brand loyalty, trust, and admiration — things money alone can’t buy.

Foam gives architects and builders something that’s often missing — control. Over shape, budget, and outcome. And when you combine that with creativity? You get architecture that speaks — not shouts — its excellence.

When a passerby stops to take a photo, not knowing why that building feels “different,” that’s when you know the design worked.

Design That Feels: Inspiration From Unexpected Places

Good design doesn’t live in a vacuum. It borrows, adapts, and reinvents. Take architectural eyewear shapes, for instance.

Good design doesn’t live in a vacuum. It borrows, adapts, and reinvents. Take architectural eyewear shapes, for instance.

The same rules that guide a building’s silhouette guide a pair of glasses: balance, tension, proportion. A bold square frame mirrors the confidence of a modernist façade. A soft round frame echoes neoclassical curves. Both make statements.

Design, whether for the human face or the cityscape, is about one thing — how it makes you feel. So when we shape foam, we’re not just chasing geometry. We’re shaping emotion, confidence, memory.

That’s why when clients see their finished building, they don’t talk about “profiles” or “coatings.” They say, “It finally feels right.”

And that’s what design, in any form, is all about.

Where Art Meets Engineering: The Human Side of Foam Craft

Every foam profile for geometric forms has a heartbeat behind it — the rhythm of hands, minds, and machines working together.

This isn’t factory monotony; it’s modern artistry.

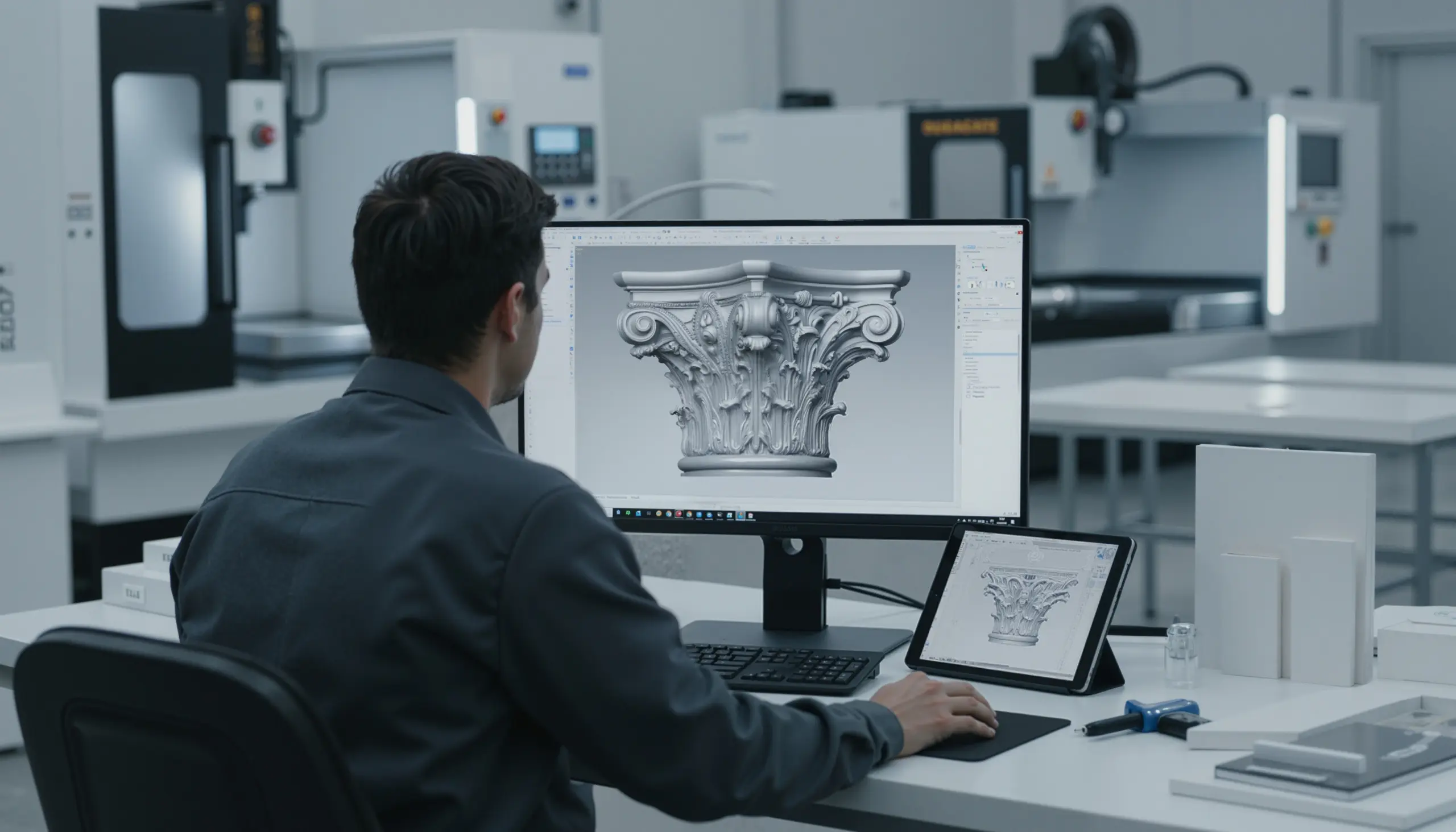

Geometric shapes allow for both speed and soul. A designer can 3D-model a complex cornice on Monday, see it CNC-cut on Tuesday, and installed by Friday. But the magic isn’t in the speed — it’s in how each shape fits perfectly, like it was always meant to be there.

One project manager once said, “You guys made us look like geniuses.”

That’s the point — we make complexity feel easy. Architectural foam shapes don’t just simplify logistics; they change how people build.

They remove the fear of experimentation — that “what if it doesn’t fit?” moment — and replace it with confidence.

Because at the end of the day, great architecture isn’t just seen. It’s felt. And foam, somehow, always finds a way to make it feel effortless.

The Future Is Foam: Why the Next Era Belongs to Lightness

In a world where deadlines get tighter and sustainability isn’t optional, foam quietly checks every box. It’s recyclable. It’s efficient. It’s precise. And it’s helping architects build smarter — not just faster.

Traditional materials will always have their place, but foam is what brings balance. It’s the future that doesn’t fight the past — it learns from it.

When the form weighs less, the idea can weigh more. And that’s how the next generation of architectural shapes will be remembered — not as alternatives, but as advancements.