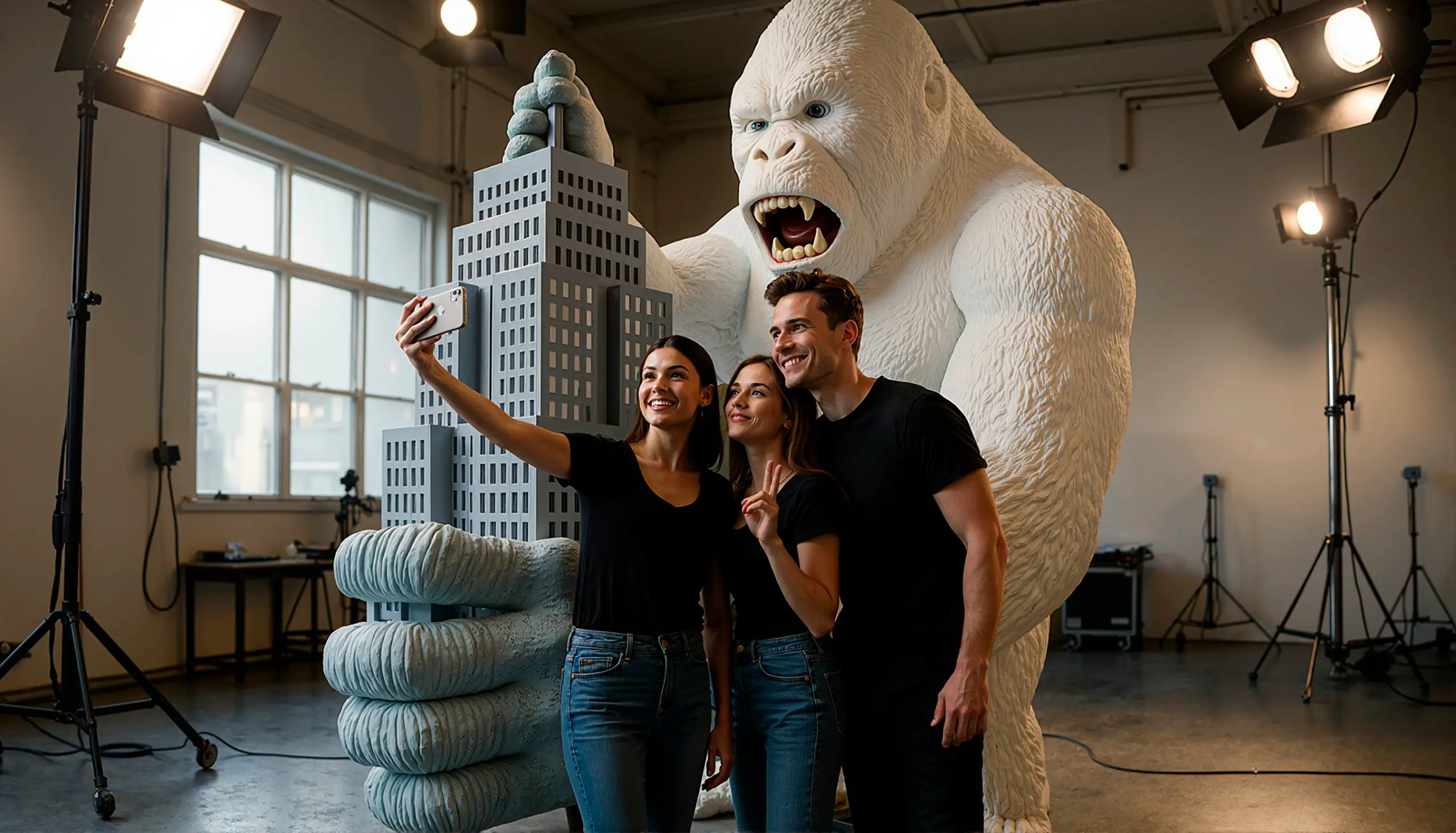

Foam stage & movie props

Is it possible to build a huge castle in a couple of hours? Or gain such superpowers that giant boulders bounce off the man harmlessly? In the world of theater and film, anything is real: you just need to know how to bring your ideas to life. And Royal Foam Art Design knows the secret to the right foam props for movies and stage: expanded polystyrene (EPS) transforms incredible concepts into a tangible reality.

Why do productions choose foam props for movies and theater

As much as it is magic to make movies and stage shows, even wizards must meet deadlines. The entertainment business is governed by timelines, limited budgets, and the desire for ideal images. Wood, plaster, and metal are slow-working materials with significant disadvantages.

As much as it is magic to make movies and stage shows, even wizards must meet deadlines. The entertainment business is governed by timelines, limited budgets, and the desire for ideal images. Wood, plaster, and metal are slow-working materials with significant disadvantages.

Large wooden props require a specialist crew and expensive transport equipment. Metal props are hazardous to work with on action scenes. Plaster decorations shatter en route and dissolve after use. Foam stage props eliminate these problems entirely.

Expanded polystyrene (EPS) means you can say goodbye to stage props weighing hundreds of pounds: now your desired object can weigh as little as 1-2 pounds per cubic foot. That means one person loads what took a crew, making load-in processes like marathons into efficient operations. So much for speedy construction superpowers!

Advantages for production teams

For production managers juggling budgets and schedules, EPS stage props deliver measurable advantages. Lower material costs reduce set construction expenses, while faster fabrication helps meet aggressive deadlines without overtime.

Added to this, when the prop weight is reduced by 100 times, it becomes much easier to carry them. This makes touring more convenient: productions are assisted greatly, as lightweight sets translate into lower transport costs and smaller crews to rig up in every theatre. Safety improvements protect cast and crew: no jagged edges, splinters, or heavy components means fewer accidents and lower insurance rates.

Where foam movie props excel: from Broadway to blockbusters

The versatility of EPS foam makes it the ideal substance for virtually any type of entertainment:

- Professional theater and touring productions. Foam stage props appear excellent after multiple uses, yet are still light enough for quick scene changes and multi-city tours.

- Film and television production. Foam movie props look realistic even when filmed close-up. This effect is achieved through professional processing, creating surfaces that the camera cannot distinguish from stone, wood, or metal.

- Concerts and music videos. Foam decorations remain pristine even during constant setup and breakdown, with surfaces holding paint beautifully under intense stage lighting. The material is also water-resistant, so you can create infinitely dramatic “dancing in the rain” scenes..

- Live shows and festivals. Outdoor events can’t dictate the weather, but EPS performs reliably in rain, heat, or cold.

- Educational and community theatre. Schools and community groups have small budgets but strive for professional-quality productions. Drama clubs gain flexibility thanks to the reusability of foam. Unlike cardboard sets, which last only one performance, foam stage props can be stored and reused for future productions, making them a wise long-term investment.

Why is expanded polystyrene used to create superior stage props

The unique properties of EPS foam make it inherently different from the materials of the past used for stage props. Expanded polystyrene is composed of granules that expand when exposed to heat and steam, forming millions of tiny air pockets. The result is 90% air by volume, explaining both minimal weight and surprising strength.

It will cut easily with a heated wire to create smooth surfaces, but resists moisture and temperature fluctuations that tend to destroy other materials.

Each property of EPS offers distinct design advantages:

- Unmatched weight-to-strength ratio. Seemingly massive props weigh almost nothing. A full-size stone castle wall, which requires a crane, can be moved by two people using EPS foam.

- Weather independence. Unique structure and durable urethane coating make our foam props unaffected by harsh weather. The material remains stable in both hot and cold environments. This eliminates prop breakage: complex shapes won’t collapse due to individual parts changing shape.

- Moisture resistance. Props won’t warp, rot, or develop mold, even in very humid warehouse environments.

- Infinite customization option. EPS foam surfaces accept virtually any coating, paint, or texture. Designers create any appearance envisioned, from rough medieval stone to sleek futuristic metal.

The technologies behind the magic

When it comes to foam stage props, Royal Foam Art Design experts know exactly what to do to achieve the most realistic results. Manufacturing begins with cutting blocks with nichrome wire heated to extreme temperatures. The wire vaporizes the material as it passes through, leaving perfectly smooth surfaces that require minimal finishing.

This precision allows reproduction of computer-generated designs with three-dimensional accuracy. Intricate curves, minute detail, and accurate measure are translated from virtual models to actual props with the consistency that hand-carving can be impossible to achieve.

Skilled technicians apply special coatings, creating textures that imitate any material: stone finishes with uneven patterns, wood grains that convey organic complexity, and metallic finishes that add gleam to iron or bronze.

Important details: safety and eco-friendliness

EPS foam is manufactured without chlorofluorocarbons (CFCs) and is hypoallergenic and non-toxic. The process consumes minimal waste since foam is cut to the finished size precisely. Foam props for movies remain reusable for years, reducing the disposable mentality.

EPS foam is manufactured without chlorofluorocarbons (CFCs) and is hypoallergenic and non-toxic. The process consumes minimal waste since foam is cut to the finished size precisely. Foam props for movies remain reusable for years, reducing the disposable mentality.

Fire protection is another aspect. In addition, EPS foam is coated with fire retardants that meet strict standards for public performance and film production.

Shapes without limits: from concept to reality

When planning a production, any director always strives to tell a truly unique story. And this quest requires specifically designed stage or movie props. Royal Foam Art Design specializes in such projects. For us, each custom order is not an extraordinary task, but a challenge we take on with a full understanding of the stage’s specifics and a complete immersion in the process.

Architectural elements and organic forms

Periodic productions require architectural details that transport audiences to specific eras. Classical columns, Gothic arches, Art Deco moldings – with EPS foam, all of these acquire an authentic look with minimal weight and cost. Building facades create depth without the need for structural features.

Natural elements are even more difficult to recreate in traditional construction. Foam liberates designers: trees carved with authentic bark textures, boulders creating dramatic landscapes without floor loads, and fantasy creatures on scales impossible with traditional materials.

Geometric designs and functional props

Modern productions require abstract forms existing as artistic statements. Geometric installations and sculptural elements can be fabricated with mathematical precision at dramatic scales that traditional materials make impossible.

Finally, we shouldn’t forget the functional props that actors use directly during filming or performance. Here, too, our custom products excel. Royal thrones and other furniture of any shape, even the most complex, can support weight while remaining light enough to be easily moved. Weapons look realistically menacing while remaining safe enough for even children to hold.

This is the magnificent balance that our specialists have managed to create over decades of work in the field.

Royal Foam Art Design for custom scenical props: we understand your vision

Choosing the right props fabrication partner determines whether creative vision becomes reality or whether compromise leads to disappointment. Royal Foam Art Design brings unmatched experience in entertainment applications, understanding custom production design needs.

Choosing the right props fabrication partner determines whether creative vision becomes reality or whether compromise leads to disappointment. Royal Foam Art Design brings unmatched experience in entertainment applications, understanding custom production design needs.

Our experience spans pilots, theater tours, streaming series, and immersive experiences. We’ve overcome challenges from hero props taking a close-up beating to complete scenic environments that whisk audiences away to other worlds.

Ordering foam props for movies or stage from us is always a collaborative process, with complete guidance right up to the time the curtain opens or “Action!” rings out. The design process can be divided into the following steps:

- First consultation with our specialist, exploring ideas, reviewing references, and discussing technical requirements;

- 3D modeling before production begins;

- A manufacturing process during which our artisans combine precision cutting with hand finishing, creating a realistic, show-ready appearance.

Our fabrication can accommodate close deadlines while maintaining quality. We’ve delivered ready-made kits with several weeks’ supply, created props for characters in just days, and provided last-minute design adjustments without missing deadlines.

For when you need props to look incredible and work flawlessly, our company provides the balance of art and engineering. Add a finishing touch to your project – order decorations from Royal Foam Art Design. To schedule a preliminary consultation, please call or email us.